Tractor Dyno: Your Guide to Power and Performance

Understanding tractor dynamometers (tractor dynos or PTO dynamometers) is crucial for maximizing tractor efficiency and farm profitability. A tractor dyno measures your tractor's horsepower and torque, providing valuable insights into its performance. This guide covers everything from choosing the right dyno to interpreting the results. For more on tractor hydraulics, see this helpful guide.

What is a Tractor Dyno?

A tractor dyno is a sophisticated testing machine that accurately measures a tractor's power output (horsepower and torque). It's essentially a comprehensive health check for your tractor's engine, revealing performance capabilities far beyond simple visual inspections. Knowing your tractor's power output isn't just about numbers; it's about informed decision-making for optimal farm operations.

Why Use a Tractor Dyno? Beyond the Numbers

Using a tractor dyno offers several key benefits:

Preventative Maintenance: Early detection of performance issues avoids costly downtime. A dyno can identify potential problems before they significantly impact your operations.

Enhanced Fuel Efficiency: Optimizing tractor settings based on dyno data leads to considerable fuel savings. This translates directly to lower operating costs. Have you considered how much fuel you are saving by making efficient adjustments?

Effective Troubleshooting: Pinpointing the source of underperformance – whether a simple adjustment or a major repair – minimizes downtime and repair costs.

Optimal Implement Matching: Ensuring your tractor and implements are well-matched maximizes productivity and prevents equipment damage. A dyno helps avoid overloading your tractor.

Data-Driven Purchasing: For used tractor purchases, a dyno test offers unbiased performance data, protecting your investment. Are you considering purchasing a used tractor? A dyno test is vital.

Types of Tractor Dynos: Finding the Right Fit

Various dyno types cater to different needs and budgets:

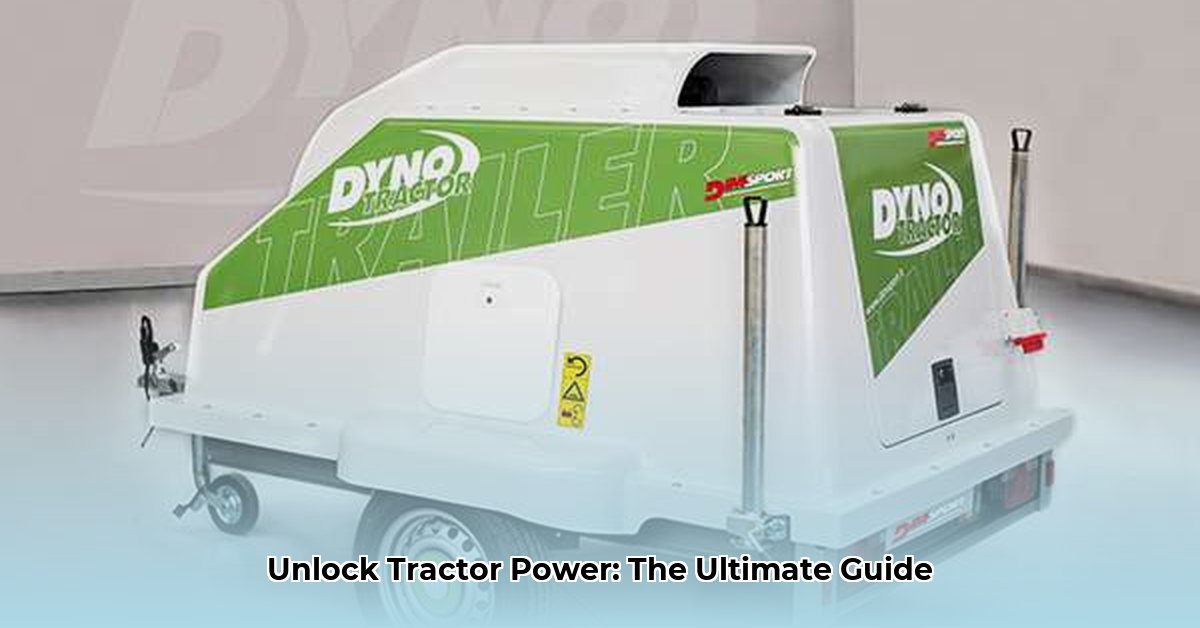

Portable Dynos: Ideal for on-farm testing due to their mobility. However, they often have lower capacity than stationary models.

Stationary Dynos: Larger and more powerful, typically found in workshops or dealerships. They’re designed for more substantial testing.

Water-Brake Dynos: An older technology, generally less accurate and less sophisticated than newer models. They are becoming less common due to technological advancement.

Hydraulic Dynos: Offer superior load control and more reliable results compared to water-brake systems, thus providing greater precision.

Electronic Dynos: The most advanced type, providing detailed data analysis and advanced features, which enhance the accuracy and efficiency of the testing.

Choosing Your Tractor Dyno: Key Considerations

Your choice depends on your specific needs and budget:

Tractor Power Output: The dyno must comfortably handle your tractor's maximum power output.

Testing Requirements: Do you need basic horsepower readings, or advanced data analysis capabilities?

Budget: Dynos vary widely in price. Consider the long-term cost of ownership, rather than focusing on the initial investment alone.

Portability: Will you test on your farm, or at a central location?

After-Sales Support: Reliable customer service and technical support are essential for long-term satisfaction.

Using a Tractor Dyno: A Step-by-Step Guide

Safe operation is paramount:

Setup: Carefully follow the manufacturer's instructions for connecting the dyno and tractor.

Calibration: Calibrate the dyno before each testing to ensure accurate results.

Test Run: Gradually increase the load on the dyno while monitoring readings on the display console.

Data Recording: Record all data accurately, including horsepower, torque, and fuel consumption.

Data Analysis: Thoroughly analyze the collected data to understand your tractor's performance profile.

Advanced Features in Modern Tractor Dynos

Modern dynos incorporate:

Smart Load Control: Automated and accurate load adjustments for consistent measurements.

Data Logging & Analysis Software: User-friendly software packages enhance data management and reporting.

Remote Monitoring: Real-time data monitoring capabilities offer enhanced convenience and manageability.

Tractor Dyno: Weighing the Pros and Cons

| Feature | Pros | Cons |

|---|---|---|

| Accuracy | Precise measurements of power and performance. | Requires careful calibration and maintenance. |

| Data Analysis | Provides detailed insights into tractor performance and fuel efficiency. | Requires expertise for comprehensive data interpretation. |

| Troubleshooting | Helps diagnose and resolve efficiency and performance problems. | Initial investment can be substantial. |

| Portability | Portable models enable on-farm testing. | Portable units have limited power capacity compared to stationary ones. |

| Cost | Wide range depending on features and capabilities. | High-end models may require specialized training. |

How to Choose the Best Agricultural PTO Dynamometer for Your Dealership

Choosing the right PTO dynamometer for a dealership requires careful consideration of several factors:

Understanding Your Needs: Horsepower and Beyond

Evaluate your dealership's typical tractor horsepower range and future growth potential. This dictates the minimum required dyno capacity. Consider whether testing will include power output and additional parameters such as fuel consumption. Advanced models offer comprehensive data acquisition and analysis software for detailed reporting.

Types of PTO Dynamometers: A Comparison

Hydraulic systems offer advantages over older water-brake systems:

| Feature | Hydraulic System | Water Brake System |

|---|---|---|

| Load Control | Precise and responsive | Less precise, prone to fluctuations |

| Cooling | Efficient cooling mechanisms | Prone to overheating under heavy loads |

| Maintenance | Generally lower maintenance requirements | More frequent maintenance required |

| Cost | Higher initial investment | Lower initial investment |

| Accuracy | Higher accuracy and repeatability | Lower accuracy and repeatability |

Technological Advancements: Data and Control

Modern dynamometers boast:

Computerized Control Systems: Enhance accuracy and data management.

Data Logging & Analysis Software: Facilitates detailed report generation, including graphical representations for better data understanding.

Choosing the Right Dynamometer: A Step-by-Step Guide

Assess your needs: Define your horsepower range, testing requirements, budget, and long-term growth plans.

Research manufacturers: Compare specifications, features, reviews, and available service support.

Evaluate software capabilities: Look for user-friendly and comprehensive software for data analysis and reporting.

Get quotes and compare pricing: Consider initial cost, maintenance, and ongoing expenses.

Conduct a trial run (if possible): Verify performance before purchasing.

Beyond the Basics: Long-Term Considerations

While initial investment is significant, consider long-term costs, including maintenance, repairs, and software updates. Investing in a high-quality dynamometer can reduce overall costs over time due to increased reliability and reduced downtime. A high-quality dynamometer, therefore, represents a sound investment.

[Citation] AW Dynamometer. PTO Dynamometers. https://awdynamometer.com/dynamometers/pto-dynamometers/